Composite Deck Spacing Tool

Guidelines • Use fasteners and hardware labeled for treated lumber — stainless-steel or hot-dipped, galvanized screws. • If the lumber is wet — it typically is when delivered from the store — butt it together tightly when building. Pressure-treated wood shrinks as it dries. • Drill pilot holes in the ends of boards to prevent splitting when you nail or screw them together. • Use wood rated for ground contact when necessary for the project. Safety • Wear a dust mask and eye protection when handling or cutting wood. • Wash your hands after working with treated wood.

• Dispose of sawdust and waste according to local regulations. • Don't burn pressure-treated wood. Software Citra Satellite Landsat. • Don't use pressure-treated wood as mulch. Read more about pressure-treated lumber and wood preservatives on the EPA website:.

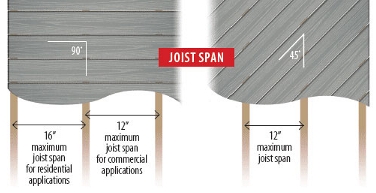

WPC has actually become a variety of natural fiber materials or inorganic materials as the substrate, and a variety of resin composite materials made of. Autodesk Auto Sketch 8. Johnson Level 60-275 Deck-Mate Deck Spacing Tool - YouTube Apr 3, 2010 Demonstration of Johnson Level's 60-275 Deck- Mate Deck Spacing Tool. Expert deck builders show you how to build a deck with composites and. Decking with PVC or composite, measure the joist spacing. Other tools for deck.

FOR USE WITH 6” PLANK DECKING (actual 5 ½”). Always refer to plank manufacturer’s specific instructions for spacing and installation. TREATED WOOD PLANK LUMBER: Use the 1/8th side of the tool. Try to use dry lumber versus wet. This will allow less contraction after your deck planks have been installed. Wood planking generally contracts and will expand and shrink over time. However, most producers of wood planks agree that a lesser amount of space between planks (side by side) is needed to allow water and debris to pass between planks.